different parts of autoclave|diagram of an autoclave : mfg The simplest form of the autoclave is the pressure cooker type or laboratory bench autoclaves. The following is the detailed description of different components/ parts of an autoclave: See more ChemValve has an innovative design for your double block and bleed needs. You will get all the advantages of the model 790EB Fully Lined Plug Valve but suitable for true double block and bleed requirements for isolation.Fig 2: Flow Chart of Manufacturing Process of AAC Blocks. The preparation of raw material consists of mixing fly ash with water to form fly ash slurry so that the fly ash can be mixed with other raw materials such as cement, gypsum, .

{plog:ftitle_list}

If the autoclave is a 3 phase 3870, 5050 or 5075 autoclave and has to be connected to a one phase power network, 1 x 230V, 50/60Hz., connected the 1ph 230V power source to the .

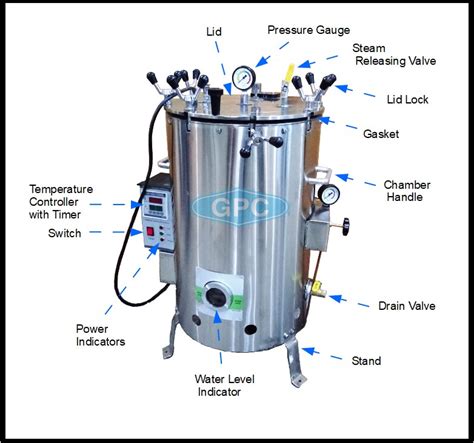

The simplest form of the autoclave is the pressure cooker type or laboratory bench autoclaves. The following is the detailed description of different components/ parts of an autoclave: See more

In general, an autoclave is run at a temperature of 121° C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. The following are the steps to be . See moreAlthough autoclaves are pretty simple to use, there are certain rules of precautions to be followed while operating an autoclave. Some of the important precautions to be followed while running an autoclave are: 1. Autoclaves should not be used to sterilize . See more

Autoclaves are important devices to ensure the sterilization of materials containing water as they cannot be sterilized by dry heat sterilization. Besides, autoclaves are used for various other purposes. 1. They are used to decontaminate . See more

The synonym for Autoclave is a “steam sterilizer.”. Table of Contents. Definition. . Autoclave Types, Components, and Sterilization Stages Explained. Explore the . Autoclave kills microorganisms using saturated stem under pressure. Autoclave .

Single Door Hinged Autoclave. Our single door hinged autoclave features a radial-arm hinged door designed for ease of use. It is available in 11 different chamber sizes ranging from 16” x 16” x 26” and 3.9 cu. ft to 24″ x 36″ x 72″ and 26 cu. ft and offers both gravity and pre-vacuum cycles. There are different brands, different configurations, and different parts, but they all work in a similar way, generating steam and heat to sterilize the materials placed inside. Most autoclave sterilizers have several main parts in common, although there are some nuances between them. The following are the most important components of an .As autoclaves operate at very high levels of pressure which can pose potential dangers for the user, the safety valve is another critical component of the autoclave. The safety valve is a fail-safe device that acts as a backup plan should electronic controls or .

For different types of material, sterilization time and temperature may vary depending on recommendations. This ensures that given materials are effectively sterilized for use. In order to understand how an autoclave works, it's important to know the different parts of this device and their respective functions. Types of Autoclave based on the different power sources. Electric autoclave machine - An electric autoclave machine is used to sterilize equipment using the moist heat sterilization concept, in which saturated steam is created under pressure to kill microorganisms. the electric autoclave machine is run by electricity and it is eco friendly.Welcome! Log into your account. your username. your password Efficient steam generation is necessary to achieve the temperatures required to eliminate microbial life, and various autoclave models may employ different methods to generate steam. Some systems are integrated, using an internal water reservoir, while others may connect to an external steam supply. The method of steam generation can impact .

The two most common types of steam sterilizers are gravity displacement autoclaves and high-speed prevacuum autoclaves. Both types of autoclave come in a variety of shapes and sizes, ranging from tabletop units to room-sized bulk units, with a vast array of customization options, such as vertical sliding doors , double-door pass-thru chambers . The Parts of an Autoclave. Autoclaves come in a variety of sizes, shapes, and designs based on their purpose. . The procedure for using an autoclave is different for the different purposes of .

types of autoclave sterilization

The Autoclave design and principle is referred from pressure cooker. And hence, in general, the autoclave is also called as pressure sterilizer. The portable autoclave can be place on working bench and called as benchtop autoclave or table top autoclave; the non portable autoclaves are placed on floor and called as floor autoclave.There are many different types of manufacturing processes. Some are designed for producing lots of components as cheaply as possible, while others are geared towards custom design. Autoclave curing is a unique procedure that offers distinct advantages for particular parts. Like all autoclaves, vertical models require routine service, performance monitoring, and proactive parts replacement to maintain peak performance. However, for vertical units, the steam generation system is typically built in, making maintenance of the heating elements and boiling area especially critical. The Autoclave was designed and invented by Charles Chamberland in the year 1879. The autoclaves now that are commercially available are with better monitoring and safety system and works on the same original principle. Principle of Autoclave: Autoclave works on the principle of steam under pressure.

lab 1 measurements and pipette use

Figure 3. 1. Vessel. The vessel is the main body of the autoclave and consists of an inner chamber and an outer jacket. Laboratory and hospital autoclaves are constructed with “jacketed” chambers (see Figure 4), where the jacket is filled with steam, reducing the time that it takes to complete a sterilization cycle and reducing condensation within the chamber.An autoclave is used to clean equipment and to keep them bacteria-free. They do this by using steam and high pressure to clean and sterilize the equipment that is placed inside them. The autoclave is used in laboratories and in other industrial settings such as food production where cleanliness of equipment is paramount. Here is a list of the main component parts that make .

Shop for our autoclave (steam sterilizer) parts for all manufacturers who utilize non-proprietary components. We stock a variety of components to ensure timely and accurate deliveries.

lab 23 12 pipette 5 ml of cola into beaker

parts and function of autoclave

Illustration showing laminate orientation . Evolution of Processes and challenges. Within the past decade or so a different processing method has been gaining in popularity; Out Of Autoclave (OOA) vacuum curing and Vacuum Bag Only (VBO) curing. These methods can offer some benefits over the autoclave process based lower initial capital and long term operating . Autoclaves are a big part of who we are. So we have dedicated content and programs to highlight the different aspects of autoclaves. Like the different parts that come together to make them for example. And with parts, comes maintenance. Autoclaves require maintenance just like any other piece of machinery does. And this includes replacement .There are different brands, different configurations, and different pieces, but they all work in similar way, creating steam and heat to sterilize materials placed inside. Most autoclaves have several primary parts in common althought there are some minor differences between them.

Easy Composites Ltd – Beginners’ Guide to Out of Autoclave Carbon Fibre Page 1 of 21 Beginners’ Guide to Out-of-Autoclave . Throughout the guide you will see photos showing us making two different parts; both genuine parts taken from our manufacturing division, Carbon Mods’ range of in-house performance parts. The two parts are a

2. The autoclave is a piece of equipment used for sterilizing various requirements in the lab by wet sterilization method. The name comes from Greek auto-, ultimately meaning self, and Latin clavis meaning key—a self-locking device. The word sterilizing means the destruction of elimination of all forms of life (microbial, including spores) present in inanimate objects by .In general, an autoclave is run at a temperature of 121°C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. The following are the steps to be followed while running an autoclave: •Before beginning to use the autoclave, it should be checked for any items left from the previous cycle. The Different Types of Autoclaves [& How to Choose the Right One] →. Steam sterilizers — also known as autoclaves — are an essential piece of equipment in any laboratory, research, or healthcare setting, ensuring sterility for important equipment and instruments.

Out of autoclave (OOA) is a process that achieves the same quality as an autoclave. The difference with OOA curing is that it achieves the elimination of voids and desired fiber content by placing the layup within a closed mold and applying vacuum, pressure, and heat by means other than an autoclave. Out of Autoclave Prepreg Carbon Fiber

Modern autoclaves use SCR drives, which form part of the closed-loop heating-control systems and can provide very fine control of the heaters. . Recorders for the display, plot, and storage of all the analog input signals such as part temperature at different locations, pressure, vacuum at different parts, and so forth; PLC (programmable .: EZ10 Autoclave Parts - Autoclave Troubleshooting Operational Manuals Maintenance Guides Maintenance Tips Free Technical Support Orthopedics & Physical Therapy Case Studies Autopsy Saw Parts Parts Installation Guides Dental Equipment Parts EXAM TABLES & CHAIRS Lab Equipment Infant Incubators & Warmers Patient Cables & Leadwires Autoclave Parts .

Autoclave consolidation is used to manufacture continuous fiber composites in applications that have strict part porosity requirements. The applied positive pressure in this process is attractive for reduction in part porosity. However, some part geometries can cause porosity issues even under positive pressure. One is the concave corner seen in an L-bracket .

how hot do autoclaves get

$31.55

different parts of autoclave|diagram of an autoclave